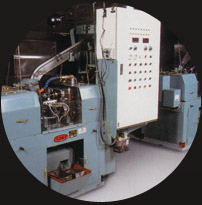

Secondary Metal Removal Operations

(Click on thumbnail to enlarge)

Skach Manufacturing Company provides its customers with a variety of secondary operations to complement our cold forming process. When converting a screw machine part to a cold formed part, a secondary operation may be required. These secondary operations are performed after cold forming (heading) a blank that in itself reduces material waste. The metal removal operations offered by Skach include drilling, tapping, grooving, trimming, cross drilling, slotting, and pointing.

Cold forming a blank with secondary operations can be a cost effective solution for your application. Forward a drawing or sample part to Skach and we can quickly determine the best approach to completing your project. We offer prototype services to insure that the conversion to a cold formed special is right for you.

Skach is ISO 9001:2015 certified and manufactures to ASME and IFI standards. We produce quality parts, on time, and at competitive prices. Contact us directly to learn more about Skach or to request a quote.

Secondary Metal Removal Operations Capabilities

- Production Capabilities

-

- Drilling

Shaving

Grooving

Cross Drilling - Tapping

Trimming

Pointing

Slotting

- Drilling

- Equipment

-

- Single and Double Spindle Drillers

Double Spindle Cross Drilling Equipment

Slotting Equipment

One and Two Tool Automatic Shavers

- Single and Double Spindle Drillers

- Materials

-

- Aluminum

Stainless Steel

Brass

Brazing Alloys

Bronze - Nickel and Nickel Alloys

Low Carbon Steel

Copper and Copper Alloys

Silver

Steel Alloys

- Aluminum

- Dimensional Limits

-

- Part Diameters up to .900"

Part Length up to 2.5"

- Part Diameters up to .900"

- Tolerances

-

- Down to +/- .0005"

- Additional Services

-

- JIT

Bar Coding

Rush Service - Inventory Management

Prototype and Short Run

Supply Chain Management

- JIT

- Products

-

- Pins

Discs

Tubular Rivets

Solid Rivets

Spheres & Balls - Threaded Fasteners & Studs

Shoulder Rivets

Electrical Contacts

Cold Headed Specials

- Pins

Print This Page

Print This Page Email This Page

Email This Page